While Swiss turning is actually a Main competency, Nanotech Precision has abilities for including micro features to Swiss-machined health care elements working with micro laser, micro EDM, or micro wire EDM capabilities. This is certainly a significant differentiator during the Swiss clinical machining realm.

When compared with injection molding, CNC machines give a faster charge of velocity. In contrast to injection molding, that may just take months to create a mildew and guarantee the machined parts are inside tolerance, CNC machining can supply things in weeks.

Properly, for A large number of products and also to the concern of how They are really manufactured, The solution is identical – CNC precision machining.

In addition, it's got provided the chance to make tools for prototyping, resulting in swift prototyping and immediate tooling. Fast prototyping offers a chance to build prototypes with a quick turnaround time.

CNC automation enables electrical discharge machining (EDM) in two means. It permits vertical EDM necessitating electrodes with an identical form and dimensions as being the cavity to generally be carved out.

Mainly because of the spinning motion produced by the CNC milling machine's cutter, the area finish of CNC machined parts could have noticeable tool marks.

Listed here, we’ve gathered some primary details and critical factors that will help you realize the desired final results.

Numerical machines are programmed with a list of instructions that go ahead and take form of letters, numbers, and symbols. Punch playing cards are used to power NC machines. NC Machines incorporate some elementary factors.

Bead Blasting: A surface area remedy process to get a specific degree of cleanliness and different roughness about the surface area of your workpiece. The surface after sandblasting is uninteresting and matt.

Musical devices need next-degree craftsmanship and precision. This is due to a slight deviation in the meant structure may lead to substantial alterations during the musical harmony from the completed product or service, properly making it faulty.

“You still should do this type of support, for the reason that when the sanctions are lifted Sooner or later, we can easily nonetheless cooperate, rather than just cutting it off,” he explained.

“I do think us meeting and attending to know one another was certainly fortuitous,” Bredikhin explained on online video.

The workpiece spins all around a central axis in CNC turning even though a linearly relocating cutting tool eliminates materials from your workpiece. As opposed to CNC mills, the cutting tool is Typically non-rotary. Single-point cutting tools are most typically used With this operation.

Inspite of the numerous benefits of CNC CNC turning for precision engineering precision machining, firms should really physical exercise caution when necessitating near tolerances.

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Tia Carrere Then & Now!

Tia Carrere Then & Now! Daniel Stern Then & Now!

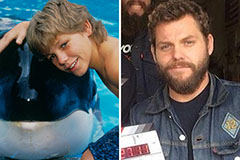

Daniel Stern Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now!